Scope of application

◇ Used in workplaces where the environment requires resistance to abrasion, impact and heavy pressure.

◇ Machinery factories, chemical factories, garages, wharves, load-carrying workshops, printing factories;

◇ Floor surfaces that need to withstand all kinds of forklift trucks and heavy-duty vehicles.

Performance characteristics

◇ Flat and bright appearance, various colours.

◇ High strength, high hardness, strong wear resistance.

◇ Strong adhesion, good flexibility and impact resistance.

◇ Flat and seamless, clean and dustproof, easy to clean and maintain.

◇ Quick construction and economical cost.

System characteristics

◇ Solvent-based, solid colour, glossy.

◇ Thickness 1-5mm.

◇ General service life of 5-8 years.

Technical index

| Test item | Indicator | |

| Drying time,H | Surface drying(H) | ≤4 |

| Solid drying(H) | ≤24 | |

| Adhesion, grade | ≤1 | |

| Pencil hardness | ≥2H | |

| Impact resistance,Kg·cm | 50 through | |

| Flexibility | 1mm pass | |

| Abrasion resistance (750g/500r, weight loss, g) | ≤0.03 | |

| Water resistance | 48h without change | |

| Resistant to 10% sulphuric acid | 56 days without change | |

| Resistant to 10% sodium hydroxide | 56 days without change | |

| Resistant to petrol, 120# | 56 days without change | |

| Resistant to lubricating oil | 56 days without change | |

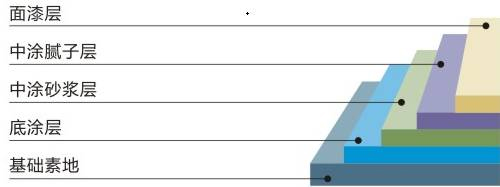

Construction process

1. Plain ground treatment: sanding clean, the base surface requires dry, flat, no hollow drum, no serious sanding;

2. Primer: double component according to the specified amount of proportioning stir (electrical rotation 2-3 minutes), with a roller or scraper construction;

3. In the paint mortar: two-component proportion according to the specified amount of quartz sand stir (electrical rotation for 2-3 minutes), with a scraper construction;

4. In the paint putty: two-component proportioning according to the specified amount of stir (electrical rotation 2-3 minutes), with a scraper construction;

5. Top coat: the colouring agent and curing agent according to the specified amount of proportioning stir (electrical rotation 2-3 minutes), with rolling or spraying construction.

Construction profile