Product alias

- Polyurethane iron red primer, polyurethane iron red anti-corrosion primer, polyurethane iron red anti-corrosion coating.

Basic parameters

| Dangerous Goods No. | 33646 |

| UN No. | 1263 |

| Organic solvent volatilisation | 64 standard m³ |

| Brand | Jinhui Coating |

| Model | S50-1 |

| Colour | Iron red |

| Mixing ratio | Main agent: curing agent=20:5 |

| Appearance | Flat and smooth surface |

Composition

- Red polyurethane primer (Red polyurethane primer) consists of hydroxyl-containing resin, iron oxide red, antirust pigmented filler, additives, solvents, etc., and a two-component polyurethane iron red paint composed of polyisocyanate prepolymer.

Characteristics

- Excellent adhesion to treated iron and steel.

- Excellent water resistance and corrosion resistance.

- Excellent anti-rust properties.

- Excellent low temperature curability.

- Fast drying and good oil resistance.

Technical parameters (part)

- Constructability: No obstacle to application

- Film appearance: Normal

- Status in the container: no hard lumps after stirring and mixing, in a uniform state.

- Drying time: surface drying ≤ 1h, solid drying ≤ 24h (standard index: GB/T1728-79)

- Salt water resistance: no cracking, no blistering, no shedding (standard index: GB/T9274-88)

- Acid resistance: no cracking, no blistering, no peeling (Standard index: GB/T9274-88)

- Alkali resistance: no cracking, no blistering, no peeling (standard index: GB/T9274-88)

- Bending resistance: 1mm (Standard index: GB/T1731-1993)

- Impact resistance: 50cm (standard index: GB/T4893.9-1992)

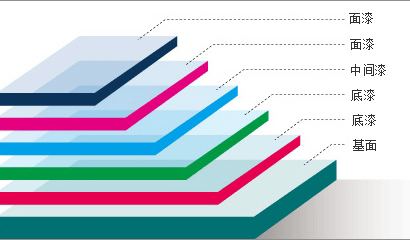

- Pre-coating: Directly painted on the steel surface whose descaling quality reaches Sa2.5 grade.

- After matching: polyurethane mica paint, polyurethane paint, acrylic polyurethane top coat, fluorocarbon top coat.

Surface treatment

- Steel surface sandblasting to Sa2.5 grade, surface roughness 30um-75um.

- Electrical tools descaling to St3 grade.

Construction parameters

- Recommended film thickness: 60-80um

- Recommended number of coats: 2~3 coats

- Storage temperature: -10~40°C

- Construction temperature: 5~40°C

- Trial period: 6h

- Construction method: Brushing, air spraying, rolling can be used.

- Theoretical dosage: about 115g/m² (based on 35um dry film, excluding loss)

- Painting interval :Substrate temperature ℃ 5-10 15-20 25-30 Shorter interval h 48 24 12 Longer interval not more than 7 days.

- Substrate temperature must be higher than the dew point of more than 3 ℃, when the substrate temperature is lower than 5 ℃, the paint film is not cured, not suitable for construction.

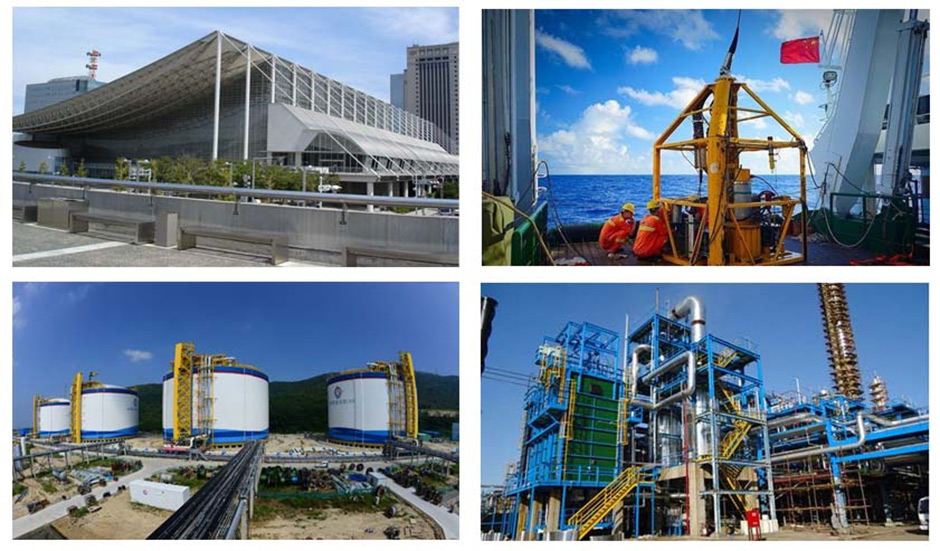

Usage

- It is suitable for steel structure, oil tank, oil tank, chemical anticorrosion equipment, electromechanical equipment, transport vehicles as antirust priming coating.

Painting construction

- After opening the barrel of component A, it must be stirred well, and then pour group B into component A under stirring according to the requirements of the proportion, mix well, leave it, cook it for 30min, add appropriate amount of diluent and adjust it to the construction viscosity.

- Diluent: special diluent for polyurethane series.

- Airless spraying: the dilution amount is 0-5% (by weight ratio of paint), the nozzle calibre is 0.4mm-0.5mm, the spraying pressure is 20MPa-25MPa (200kg/cm²-250kg/cm²).

- Air spraying: Dilution amount is 10-15% (by weight ratio of paint), nozzle calibre is 1.5mm-2.0mm, spraying pressure is 0.3MPa-0.4MPa (3kg/cm²-4kg/cm²).

- Roller coating: Dilution amount is 5-10% (by paint weight ratio)

Caution

- In the high temperature season construction, easy to dry spray, in order to avoid dry spray can be adjusted with thinner until not dry spray.

- This product should be used by professional painting operators according to the instructions on the product package or this manual.

- All work involving the application and use of this product must be carried out in accordance with all relevant health, safety and environmental regulations and standards.

- If in doubt as to whether this product should be used, please contact our Technical Service Department for details.

Packaging

- Component A (paint): 20kg drum

- Component B (hardener): 5kg drum

Transport Storage

- Products should be stored in a cool and ventilated place, preventing direct sunlight, and isolated from sources of ignition, away from heat sources in the warehouse.

- When transporting the product, it should be protected from rain and sunlight, avoid collision, and conform to the relevant regulations of the traffic department.

Safety Protection

- The construction site should have good ventilation facilities, and painters should wear glasses, gloves, masks, etc. to avoid skin contact and inhalation of paint mist.

- Smoking and fire are strictly prohibited at the construction site.