For underground car park floors, common flooring solutions include: epoxy flooring, hard wearing flooring and hardened penetrant flooring.

Epoxy flooring: garage epoxy flooring

Epoxy flooring, that is, epoxy resin floor paint as the main material, with quartz sand/powder as auxiliary materials, using grinding, vacuuming, scraping, rolling or spraying and other construction methods, to get the floor surface. After the construction of the ground, the epoxy layer covers the grass-roots cement concrete, thus fundamentally isolating the grass-roots concrete from possible problems such as sand, dust and so on. Epoxy floor surface, dust-free, wear-resistant, easy to clean, bright colour.

Commonly used as a car park floor epoxy flooring solutions are: mortar type epoxy flooring, thin coating type epoxy flooring, self-levelling type epoxy flooring.

Mortar type epoxy flooring, the process is generally: substrate grinding and cleaning, one epoxy primer, one or two epoxy mortar, two epoxy putty, two epoxy surface coating. The thickness is between 0.8-1.5mm.

Thin coating type epoxy flooring, the process is generally: substrate grinding and cleaning, one epoxy primer, one epoxy mortar, one epoxy putty, one epoxy surface coating. The thickness is between 0.5-0.8mm.

Self-levelling type epoxy flooring, the process is generally: substrate grinding and cleaning, one epoxy primer, two epoxy mortar, one epoxy putty, one epoxy flow plane coating. The thickness is between 2-3mm.

Thin coating type epoxy flooring, only in the ground foundation is very flat, concrete strength is very good, and the cost budget is very limited, the apparent effect of the requirements of the case is not high, generally not recommended. Mortar type epoxy flooring, compared with thin coating type epoxy flooring, the surface is more flat, delicate, wear resistance, impact resistance is stronger, is the underground car park epoxy flooring programme. Self-levelling epoxy flooring is only used in government agencies, Olympic venues and other national projects for underground car parks. In addition, individual projects, the user in the case of not pursuing the surface flatness and sensory effects, just to solve the cement concrete surface of the sand, dust, there are two epoxy primer, two epoxy top coating of the simple epoxy flooring programme.

Therefore, the decisive factor for choosing what kind of epoxy flooring programme is, firstly, the ground foundation, secondly, what kind of effect is required to be achieved, and then the cost budget. Between the three are clear, complementary.

Wear-resistant flooring

Cement-based wear-resistant flooring materials, composed of special cement, wear-resistant aggregate (quartz sand, emery, tin-titanium alloy, etc.) and additives and other components, to scientifically reasonable grading using factory premixed way to produce out of the bag, powder.

The construction of wear-resistant flooring is synchronised with the construction of cement concrete. After normal paving, levelling and vibration of cement concrete on the surface of underground car park, the wear-resistant flooring material will be spread to the surface in the initial solidification stage, and the wear-resistant material will be constructed as a whole with cement concrete through the special tool of flooring construction, the smoothing machine, so as to form a protective layer in the surface layer of cement concrete.

As we all know, most of the general underground car park cement concrete C20, C25 standard, C25 concrete, for example, the surface compressive strength of about 25MPA. But after the construction of wear-resistant flooring, the compressive strength of the surface can reach 80MPA, or even more than 100MPA, and other flexural strength, wear-resistant strength and other indicators have also been significantly improved.

Because wear-resistant flooring belongs to cement-based products, so it can be well combined with cement concrete, as long as the grass-roots concrete is not broken, wear-resistant flooring for decades without breakage, without shedding. At the same time, the colour is not as gorgeous and rich as epoxy flooring, which is generally grey, green, red and other basic colours.

Ordinary cement concrete, due to improper production and construction, or weathering over the years, it is easy to turn sand, dust phenomenon, that is, cement concrete in the sand, stone and cement separation. This kind of ground car park, environmental cleaning is very troublesome, the surface of the parked vehicles is covered with dust, the owner complains a lot. Wear-resistant flooring is an economical and practical solution to this problem. Ground no longer appear sand and dust phenomenon, and with the vehicle's grinding and friction, wear-resistant ground will be up to a certain degree of luster.

General underground car park wear-resistant flooring, mostly quartz sand type and diamond type wear-resistant flooring. The colour is mostly cement colour or grey.

hardening penetrant flooring

Garage penetrant flooring is directly on the concrete floor, sand wear-resistant flooring, terrazzo flooring, etc., if the garage has been poured concrete and calendared ground, it is recommended to do directly Yade's penetrant flooring, construction is simple, the technical indicators and wear-resistant flooring is comparable to the later maintenance is very simple, which is also the advantage of the garage penetrant flooring. Yade flooring when the initial intention of the development of penetrant flooring, is to find a substitute for epoxy flooring, but also wear-resistant flooring durable wear-resistant advantages, penetrant flooring after the construction of the colour is not up to the epoxy flooring as colourful, but the difference is not big, the difference between the two lies in the thickness of the epoxy floor is a certain thickness, once the construction of the bad, it is very easy to peel off the skin phenomenon, and the late renovation and maintenance is very cumbersome, and the role of the mechanism of Yade flooring. Penetrant flooring mechanism is to the concrete floor penetration, and react with concrete, and finally make the surface form a closed whole, not only solves the concrete sanding and grey phenomenon at the same time can also greatly increase the hardness of the concrete surface, and at the same time on the acid and alkali solution play a certain role in isolation, more and more homeowners in the market use penetrant flooring as the first garage flooring.

Outdoor car park common construction programme

Outdoor car park can be used: colour permeable concrete floor, art embossed flooring.

Common construction solutions for garage ramp flooring

Garage ramp flooring can be used: non-vibration non-slip driveway, sand non-slip ramp

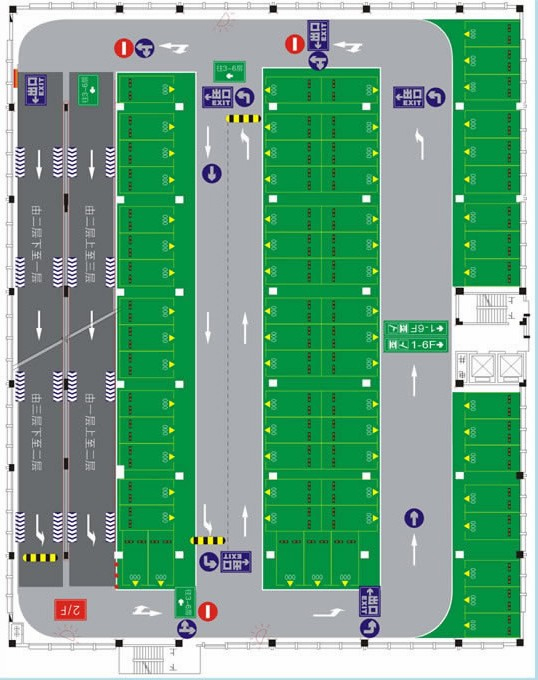

Garage plan design

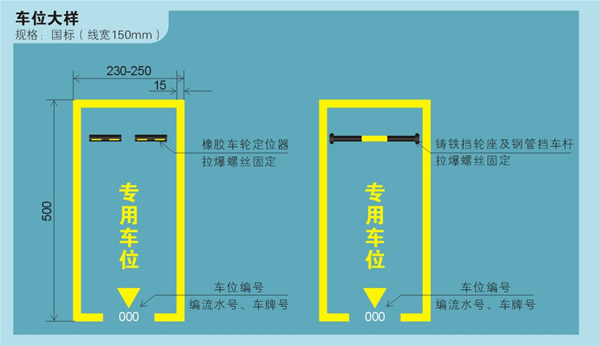

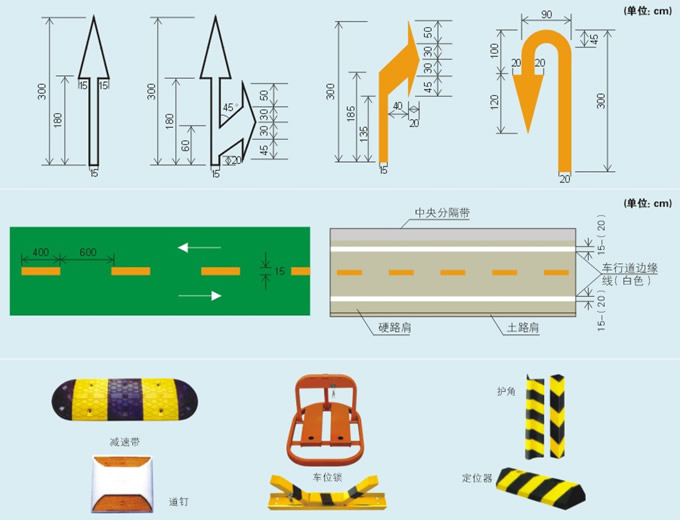

Garage signs and facilities