Product aliases

Alkyd paint, alkyd top coat, alkyd paint, alkyd anticorrosive paint, alkyd anticorrosive top coat, alkyd magnetic top coat.

Basic parameters

| Product English Name | Alkyd topcoat |

| Product Chinese Name | Alkyd Magnetic Topcoat |

| Dangerous Goods No. | 33646 |

| UN No. | 1263 |

| Organic solvent volatility | 64 standard metre³. |

| Brand | Jinhui paintings |

| Model No. | C52-5 |

| Colour | Colour |

| Mixing ratio | One-component |

| Appearance | Smooth surface |

Product composition

Alkyd Magnetic Paint is a magnetic paint composed of alkyd resin, additives, No.200 solvent gasoline and mixed solvents, and drying agent.

Characteristics

- Paint film resistance to chalking, good protection performance, good light retention and colour retention, bright colour, good durability.

- It has good adhesion to metal and wood, and has certain water resistance and salt water resistance.

- Tough paint film, good sealing, excellent anti-rust performance, can withstand the impact of temperature difference.

- Good weather resistance, gloss and hardness.

- High pigment content, good sanding performance.

- Strong adhesion, good mechanical properties.

- Strong filling ability.

- Good construction performance.

Technical parameters: GB/T 25251-2010

- Status in the container: no hard lumps after stirring and mixing, in a homogeneous state.

- Fineness: ≤40um (standard index: GB/T6753.1-2007)

- Salt water resistance: 3% NaCl, 48h without cracking, blistering or peeling (Standard index: GB/T9274-88)

- Non-volatile matter content: ≥50% (standard index: GB/T1725-2007)

- Water resistance: 8h without cracking, blistering or peeling (Standard index: GB/T9274-88)

- Drying time: surface drying ≤ 8h, real drying ≤ 24h (standard index: GB/T1728-79)

Surface treatment

Steel surface sandblasting treatment to Sa2.5 grade, surface roughness 30um-75um.

Electrical tools descaling to St3 grade.

Front course matching

Alkyd primer, alkyd mica intermediate paint.

Construction parameters

| Recommended film thickness | 60-80um |

| Theoretical dosage | about 120g/m² (based on 35um dry film, excluding loss) |

| Recommended number of coats | 2~3 coats |

| Storage temperature | -10~40℃ |

| Construction temperature | 5~40℃. |

| Trial period | 6h |

| Construction method | Brushing, air spraying, rolling can be. |

| Coating interval | Substrate temperature ℃ 5-10 15-20 25-30 |

| Shorter interval h 48 24 12 | |

| The longer interval should not exceed 7 days. | |

| Substrate temperature must be more than 3℃ above the dew point, when the substrate temperature is lower than 5℃, the paint film will not be cured and should not be constructed. | |

Painting construction

After opening the barrel, it must be stirred evenly, left to stand, and after maturing for 30min, add appropriate amount of thinner and adjust to the construction viscosity.

Diluent: special diluent for alkyd series.

Airless spraying: Dilution amount is 0-5% (by weight ratio of paint), nozzle calibre is 0.4mm-0.5mm, spraying pressure is 20MPa-25MPa (200kg/cm²-250kg/cm²).

Air spraying: Dilution amount is 10-15% (by weight ratio of paint), nozzle calibre is 1.5mm-2.0mm, spraying pressure is 0.3MPa-0.4MPa (3kg/cm²-4kg/cm²).

Roller coating: Dilution amount is 5-10% (by paint weight ratio).

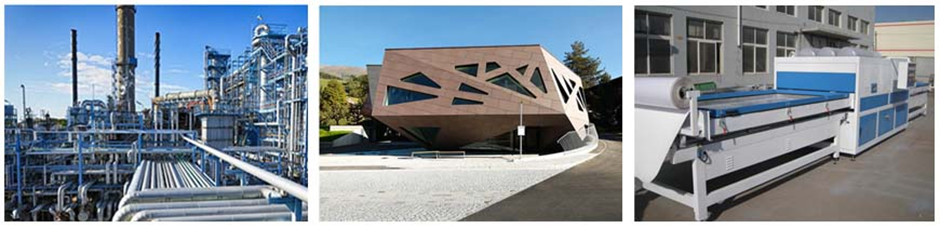

Usage

Suitable for steel surfaces, mechanical surfaces, pipeline surfaces, equipment surfaces, timber surfaces, indoor and outdoor metal surfaces and timber surfaces to protect and decorate, it is a general-purpose paint, widely used in construction, machinery, vehicles and various decorative industries.

Note

Dry spraying is likely to occur during the hot season:

- In the high temperature season construction, easy to dry spray, in order to avoid dry spray can be adjusted with thinner until not dry spray.

- This product should be used by professional painting operators according to the instructions on the product package or this manual.

- All coating and use of this product must be carried out in accordance with all relevant health, safety and environmental regulations and standards.

- If in doubt as to whether or not to use this product, please contact our technical service department for details.

Packaging

25kg drum.

Transport and storage

The product should be stored in a cool and ventilated place, prevented from direct sunlight, and isolated from sources of ignition, away from heat sources in the warehouse.

When transporting the product, it should be prevented from rain, sunlight exposure, avoid collision, and should comply with the relevant regulations of the traffic department.

Safety Protection

The construction site should have good ventilation facilities, and painters should wear glasses, gloves, masks, etc. to avoid skin contact and inhalation of paint mist.

Smoke and fire are strictly prohibited at the construction site.

Customer's Frequently Asked Questions

Is it easy to paint white and light-coloured topcoats after applying Iron Red Anti-Rust?

A: Conventional alkyd enamels cannot be applied to the above surfaces.

Can the topcoat be painted on plastic, aluminium and galvanised surfaces?

A: No, it is not easy, you need to apply two more coats of topcoat.

Construction and storage and transport

1、According to the construction, use alkyd thinner to adjust the viscosity.

2、The paint can be brushed, rolled or sprayed.

3、Before construction, should remove the substrate of oil, impurities, dust and rust. Relative humidity greater than 85% should not be constructed, the construction personnel should strengthen their own protection, wear a good safety gear to prevent the paint mist inhaled and splashed on the skin.

4、The product should be placed in a dry and cool warehouse, shelf life of 12 months. 5, storage and transport process, should be strictly prohibited collision, sun, rain, and away from sources of fire.

Construction reference:

- Spraying: air pressure 0.3 ~ 0.4 Mpa viscosity 18 ~ 22 S / paint -4 cups

- Brush: applicable

- Diluent: special diluent

- Theoretical usage: 110~130g/square metre

- Matching primer: iron red alkyd primer, ferric alkyd anti-rust paint, etc.

- Safety precautions: This product is flammable, storage and construction places, pay attention to ventilation, cooling, away from fire.

- Storage: Store in cool and dry environment, effective storage period of one year. If the storage period exceeds one year, the product can still be used if it meets the requirements after inspection.

- Spraying, brushing can be, dry or dry at room temperature (drying temperature 60-70 degrees)

- Thickness of each layer is 15-20 microns, the first dry and then apply the second.

- It can be thinned with turpentine and 200# petroleum solvent oil and xylene and other solvents.

- Requirements for alkyd magnetic paint: apply alkyd primer first and then use alkyd putty to make up the flatness, and finally apply alkyd magnetic paint.