Product aliases

- Alkyd antirust paint, alkyd iron red anticorrosive primer, alkyd primer, alkyd grey primer, alkyd iron red paint

Basic parameters

| English name | Alkyd anti-corrosion primer |

| Dangerous Goods No. | 33646 |

| UN No. | 1263 |

| Organic solvent volatility | 64 standard metre³. |

| Brand | Jinhui Coatings |

| Model No. | C52-1-5 |

| Colour | Iron red, grey |

| Mixing ratio | Single component |

| Appearance | Smooth surface |

Product Ingredients

- Alkyd anticorrosive primer is a one-component primer composed of alkyd resin, iron oxide red, antirust pigmented filler, additives, No.200 solvent gasoline and mixed solvent, and catalytic agent.

Characteristics

- Poor in solvent resistance (petrol, alcohol, etc.), acid and alkali resistance, chemical resistance, and slow drying speed.

- Paint film resistance to chalking, good protection performance, good light and colour retention, bright colour, good durability.

- Tough film, good sealing, excellent rustproof performance, can withstand the impact of temperature difference.

- Good matching performance, good combination with alkyd top coat.

- High pigment content, good sanding performance.

- Strong adhesion, good mechanical properties.

- Strong filling ability.

- Good construction performance.

Technical parameters: GB/T 25251-2010

- Status in the container: no hard lumps after stirring and mixing, in a homogeneous state.

- Fineness: ≤50um (standard index: GB/T6753.1-2007)

- Salt water resistance: 3% NaCl, 24h without cracking, blistering or peeling (Standard index: GB/T9274-88)

- Drying time: surface drying ≤ 5h, solid drying ≤ 24h (standard index: GB/T1728-79)

Surface treatment

- Steel surface sandblasting treatment to Sa2.5 grade, surface roughness 30um-75um.

- Electrical tools to remove rust to St3 grade.

Paint construction

- After opening the barrel, it must be stirred evenly, left to stand and mature for 30min, then add appropriate amount of thinner and adjust to the construction viscosity.

- Diluent: special diluent for alkyd series.

- Airless spraying: Dilution amount is 0-5% (by weight ratio of paint), nozzle calibre is 0.4mm-0.5mm, spraying pressure is 20MPa-25MPa (200kg/cm²-250kg/cm²).

- Air spraying: Dilution amount is 10-15% (by weight ratio of paint), nozzle calibre is 1.5mm-2.0mm, spraying pressure is 0.3MPa-0.4MPa (3kg/cm²-4kg/cm²).

- Roller coating: Dilution amount is 5-10% (by paint weight ratio).

Usage

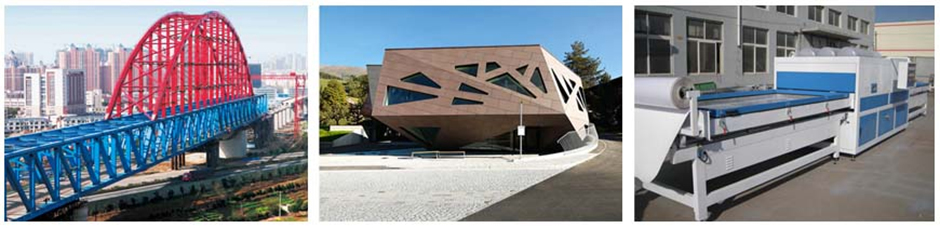

- Alkyd primer can be used as the primer of alkyd magnetic paint with high decorative requirements, suitable for wood and steel surfaces; suitable for steel surfaces, mechanical surfaces, pipeline surfaces, equipment surfaces, wood surfaces; alkyd primer is only used as the matching primer of the recommended alkyd paint and the matching primer of nitro paints, asphalt paints, phenolics paints and so on, and it can't be used as the matching antirust paint of the double-component paints and strong solvent paints.

Note

Dry spraying is likely to occur during the hot season:

- In the high temperature season construction, easy to dry spray, in order to avoid dry spray can be adjusted with thinner until not dry spray.

- This product should be used by professional painting operators according to the instructions on the product package or this manual.

- All coating and use of this product must be carried out in accordance with all relevant national health, safety and environmental regulations and standards.

- If in doubt as to whether this product should be used, please contact our technical service department for details.

Packaging

- 25kg drum

Transport and storage

- The product should be stored in a cool and ventilated place, prevented from direct sunlight, and isolated from sources of ignition, away from heat sources in the warehouse.

- When transporting the product, it should be prevented from rain, sunlight exposure, avoid collision, and should comply with the relevant regulations of the traffic department.

Safety Protection

- The construction site should have good ventilation facilities, and painters should wear glasses, gloves, masks, etc. to avoid skin contact and inhalation of paint mist.

- Smoking and fire are strictly prohibited at the construction site.