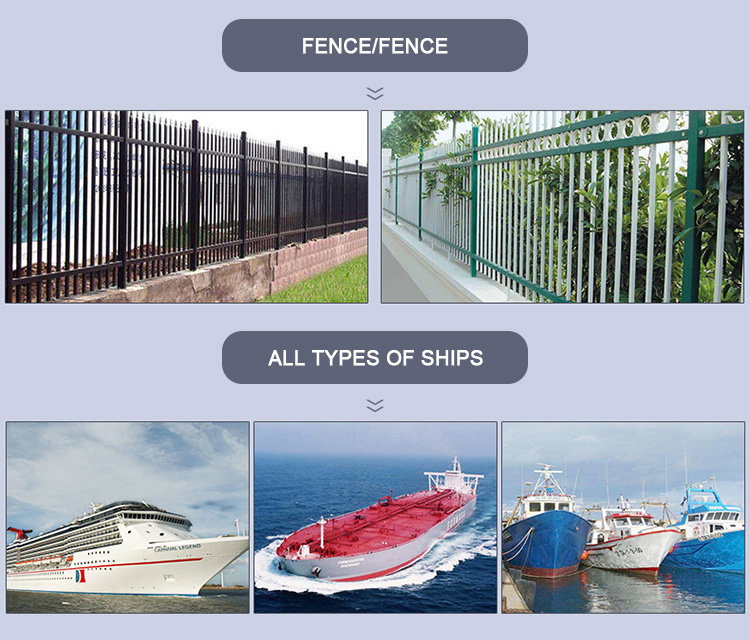

Ships Bridges Anti-corrosion Paint Epoxy Zinc-Rich Primer Epoxy Coating

Product Description

- Epoxy zinc-rich primer belongs to epoxy resin paint, which is composed of epoxy resin, zinc powder, polyacyl resin and other materials. Epoxy zinc-rich primer is an anti-rust primer. The zinc content of epoxy zinc-rich primer is high, and the electrochemical reaction produced by zinc powder makes the coating film of epoxy zinc-rich primer have good anti-rust and anti-corrosion ability.

- Epoxy zinc-rich primer is widely used in the coating of various steel structures under atmospheric environment. For example: Bridges, containers, iron towers, ship hulls, building steel structures, etc.

Main features

- High zinc content

Epoxy zinc-rich primer is produced with high quality zinc powder, high zinc powder content, which can effectively protect the substrate, and various content specifications can be customized.

- Cathodic protection

Zinc powder has cathodic protection, plays an electrochemical anticorrosion function, sacrificial anode to protect the cathode, especially suitable for long-term anticorrosion field.

- weldability

The welding operation with the coating does not affect the quality of the welding, and the coating is not damaged by cutting or welding.

- Strong adhesion

The paint film has very excellent adhesion to the surface of the sandblasted steel, the coating does not fall off, and the adhesion is firm.

- Matching performance

Epoxy zinc-rich primer as a heavy anti-corrosion primer, with a variety of intermediate paint, top paint to form a supporting system, supporting a variety of programs.

- Corrosion inhibition protection

Zinc powder reacts with the corrosive medium to produce dense zinc salt, which can block the further corrosion shielding, protect the steel and play the role of corrosion inhibition.

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | Stocked item: 3~7 working-days Customized item: 7~20 working days |

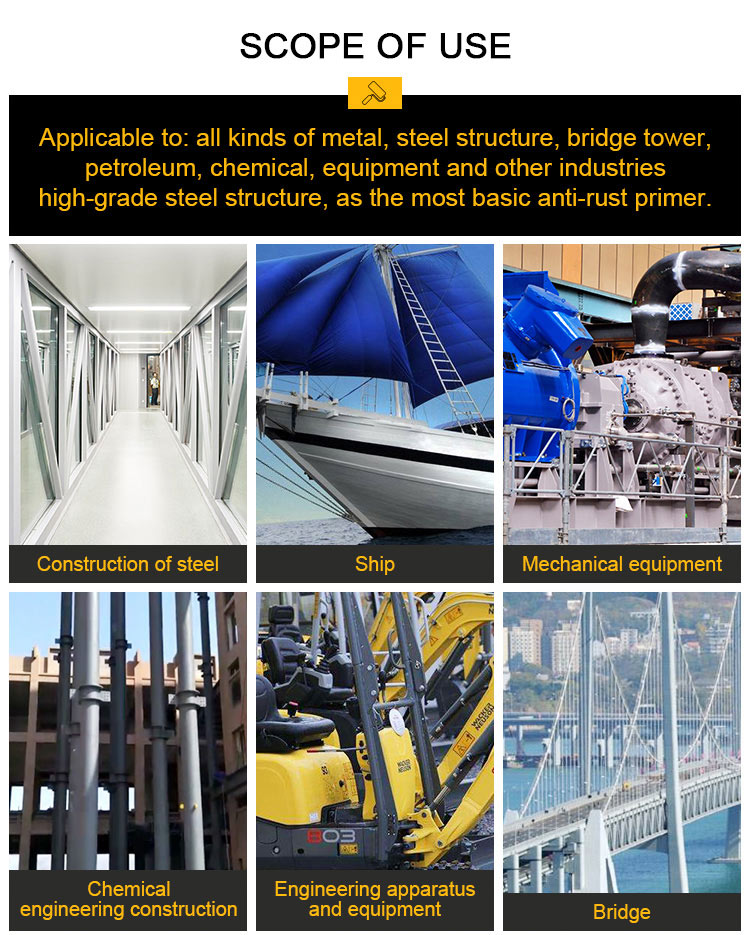

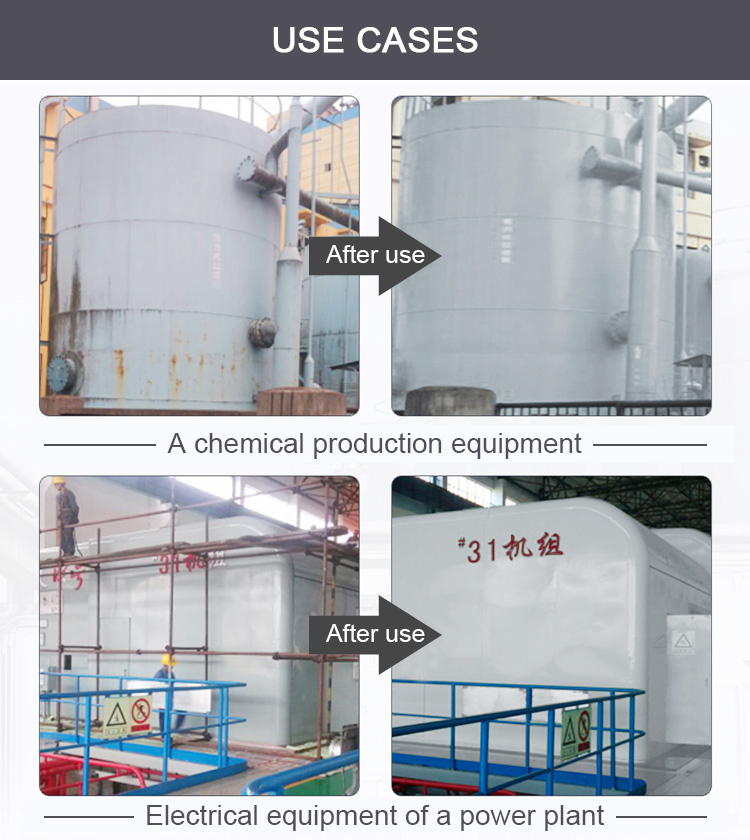

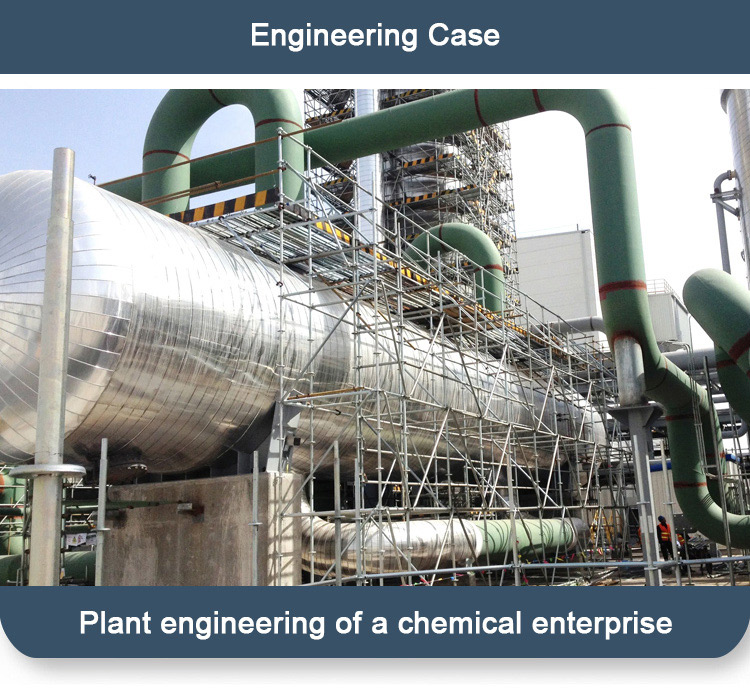

Main uses

Epoxy zinc-rich primer is used as anti-corrosion and anti-rust primer for steel components, especially suitable for harsh corrosion environment or medium and long-term anti-corrosion requirements. For example, steel structure bridge anticorrosion, storage tank external anticorrosion, container anticorrosion, steel structure anticorrosion, port facilities anticorrosion, plant construction anticorrosion and so on.

Scope of application

Construction reference

1, The surface of the coated material must be free of oxide, rust, oil and so on.

2, The substrate temperature must be above 3 ° C above zero, when the substrate temperature is below 5 °C, the paint film is not solidified, so it is not suitable for construction.

3, After opening the bucket of component A, it must be stirred evenly, and then pour group B into component A under stirring according to the ratio requirement, fully mixed evenly, standing, and curing After 30 mins, add an appropriate amount of diluent and adjust to the construction viscosity.

4, The paint is used up within 6h after mixing.

5, Brush coating, air spraying, rolling coating can be.

6, The coating process must be constantly stirred to avoid precipitation.

7, Painting time:

| Substrate temperature (°C) | 5~10 | 15~20 | 25~30 |

| Minimum interval (Hour) | 48 | 24 | 12 |

The maximum interval should not exceed 7 days.

8, recommended film thickness :60~80 microns.

9, dosage: 0.2~0.25 kg per square (excluding loss).

Transportation and storage

1, Epoxy zinc-rich primer in transportation, should prevent rain, sunlight exposure, to avoid collision.

2, Epoxy zinc-rich primer should be stored in a cool and ventilated place, prevent direct sunlight, and isolate the fire source, away from the heat source in the warehouse.

About us

Our company has always been adhering to the "science and technology, quality first, honest and trustworthy", strict implementation of ISO9001:2000 international quality management system.Our rigorous management,technological innovation, quality service cast the quality of products, won the recognition of the majority of users.As a professional standard and strong Chinese factory, we can provide samples for customers who want to buy, if you need Epoxy Zinc-rich Primer Paint, please contact us.