Inorganic Zinc Rich Primer Coating Anti-Corrosion Steel Industrial Paint

Product Description

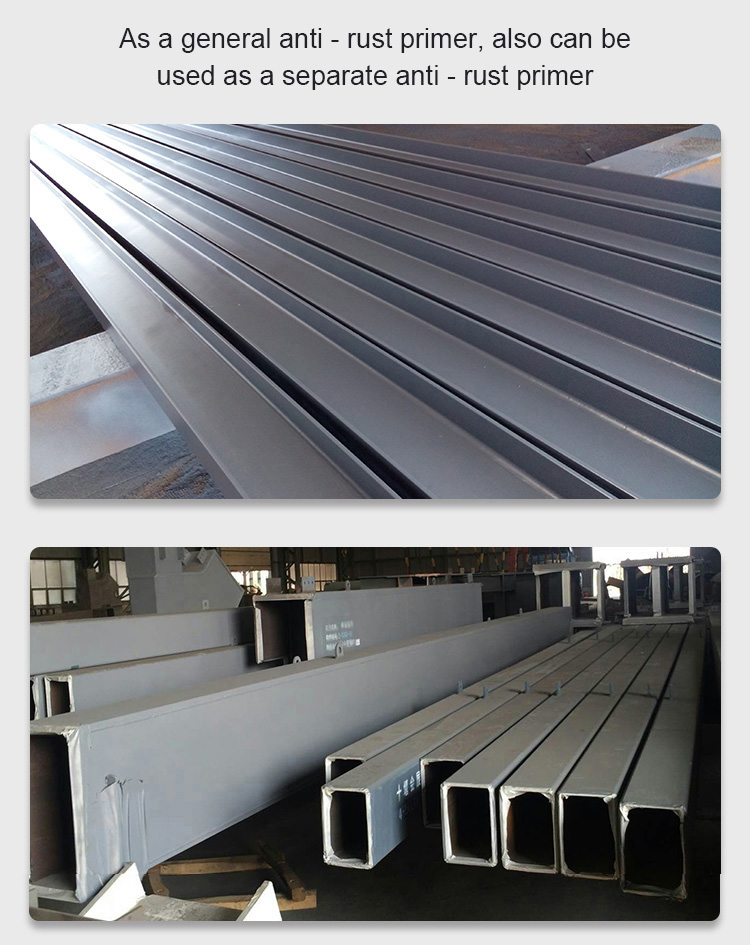

Inorganic zinc rich primer paint for the steel structure after painting and external treatment, it has good adhesion, fast surface drying and practical drying, good rust prevention performance, water resistance, salt resistance, resistance to various oil immersion and high temperature resistance.

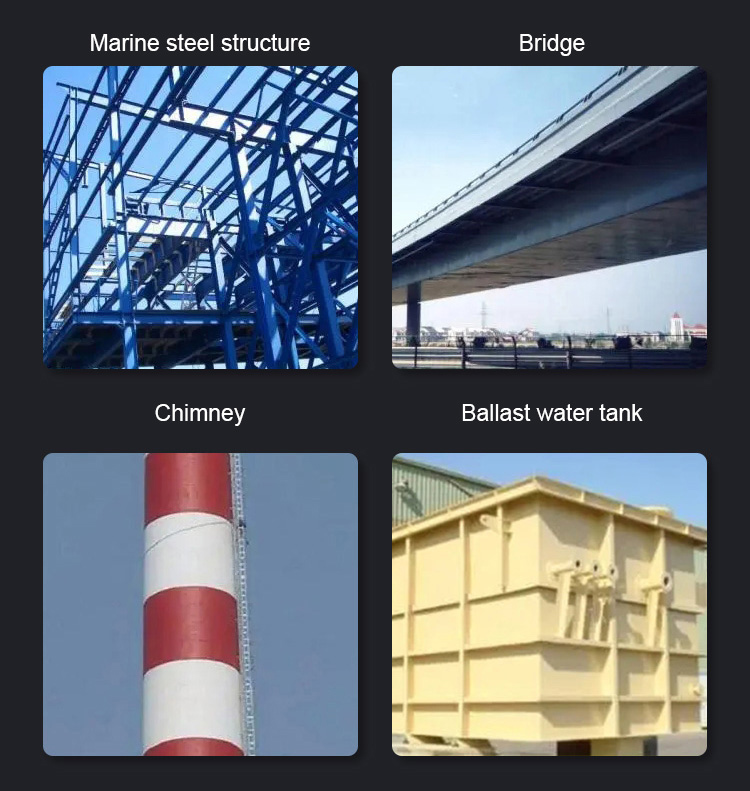

Inorganic zinc rich primer is applied to anti-corrosion of ships, sluices, vehicles, oil tanks, water tanks, bridges, pipelines and outer walls of oil tanks. The color of the paint is gray. The material is coating and the shape is liquid. The packaging size of the paint is 4kg-20kg. Its characteristics are high temperature resistance,water resistance, salt resistance, resistance to various oil immersion resistance.

Our company has always been adhering to the "science and technology, quality first, honest and trustworthy", strict implementation of ISO9001:2000 international quality management system.Our rigorous management,technological innovation, quality service cast the quality of products, won the recognition of the majority of users.As a professional standard and strong Chinese factory, we can provide samples for customers who want to buy, if you need Inorganic zinc rich primer Paint, please contact us.

Main Composition

The product is a two-component self-drying coating composed of medium molecular epoxy resin, special resin, zinc powder, additives and solvents, The other component is an amine curing agent.

Main features

Rich in zinc powder, zinc powder electric chemical protection effect makes the film has a very outstanding rust resistance: high hardness of the film, high temperature resistance, does not affect the welding performance: drying performance is superior; High adhesion, good mechanical properties.

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | stocked item: 3~7 working-days customized item: 7~20 working days |

Main Uses

Widely used in metallurgy, containers, all kinds of traffic vehicles, engineering machinery steel plate pretreatment shot blasting, especially suitable for steel structure rust prevention, is the ideal metal pretreatment shot blasting and rust prevention maintenance primer.

Coating method

Airless spraying: thinner: special thinner

Dilution rate :0-25%(according to paint weight)

Nozzle diameter: about 04~0.5mm

Ejection pressure :15~20Mpa

Air spraying:Thinner: special thinner

Dilution rate :30-50%(by weight of paint)

Nozzle diameter: about 1.8~2.5mm

Ejection pressure :03-05Mpa

Roller/brush coating:Thinner: special thinner

Dilution rate :0-20%(by weight of paint)

Storage life

The effective storage life of the product is 1 year, expired can be checked according to the quality standard, if meet the requirements can still be used.

Note

1. Before use, adjust the paint and hardener according to the required ratio, mix as much as needed and then use after mixing evenly.

2. Keep the construction process dry and clean. Do not contact with water, acid, alcohol, alkali, etc. the curing agent packaging barrel must be tightly covered after painting, so as to avoid gelling;

3. During construction and drying, the relative humidity shall not be greater than 85%. This product can only be delivered 7 days after coating.