Fluorocarbon anticorrosive topcoat industrial fluorocarbon coating finish paint

Product Description

- Fluorocarbon topcoat contains F-C chemical bond, has excellent stability, strong resistance to ultraviolet light, outdoor coating can protect for more than 20 years. The protective effect of fluorocarbon top paint is significant, mainly used in areas where the corrosive environment is harsh or the decoration requirements are high, such as bridge steel structure, concrete exterior wall painting, building venues, guardrail decoration, port facilities, Marine equipment anticorrosion, etc.

- Fluorocarbon paint is the best anticorrosive and rust-proof coating at present. Fluorocarbon paint refers to the coating with fluorine resin as the main film-forming substance. Also known as fluorine coatings, fluorine resin coatings and so on. Among all kinds of coatings, fluorine resin coatings have particularly superior properties due to the introduction of fluorine element electronegativity and strong carbon-fluorine bond energy. Weather resistance, heat resistance, low temperature resistance, chemical resistance, and has a unique non-viscosity and low friction.

Technical specification

| Appearance of coat | The coating film is smooth and smooth | ||

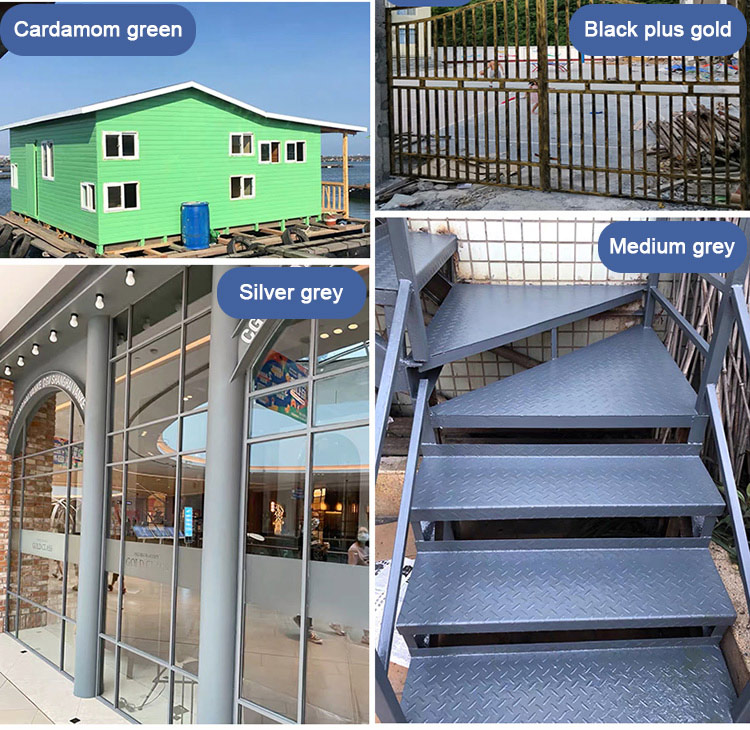

| Color | White and various national standard colors | ||

| Drying time | Surface dry ≤1h (23°C) Dry ≤24 h(23°C) | ||

| Fully cured | 5d (23℃) | ||

| Ripening time | 15min | ||

| Ratio | 5:1 (weight ratio) | ||

| Adhesion | ≤1 level (grid method) | ||

| Recommended coating number | two, dry film 80μm | ||

| Density | about 1.1g/cm³ | ||

| Re-coating interval | |||

| Substrate temperature | 0℃ | 25℃ | 40℃ |

| Time length | 16h | 6h | 3h |

| Short time interval | 7d | ||

| Reserve note | 1, coating after the coating, the former coating film should be dry, without any pollution. 2, should not be in rainy days, foggy days and relative humidity greater than 80% of the case. 3, before use, the tool should be cleaned with diluent to remove possible water. should be dry without any pollution |

||

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | Stocked item: 3~7 working-days Customized item: 7~20 working days |

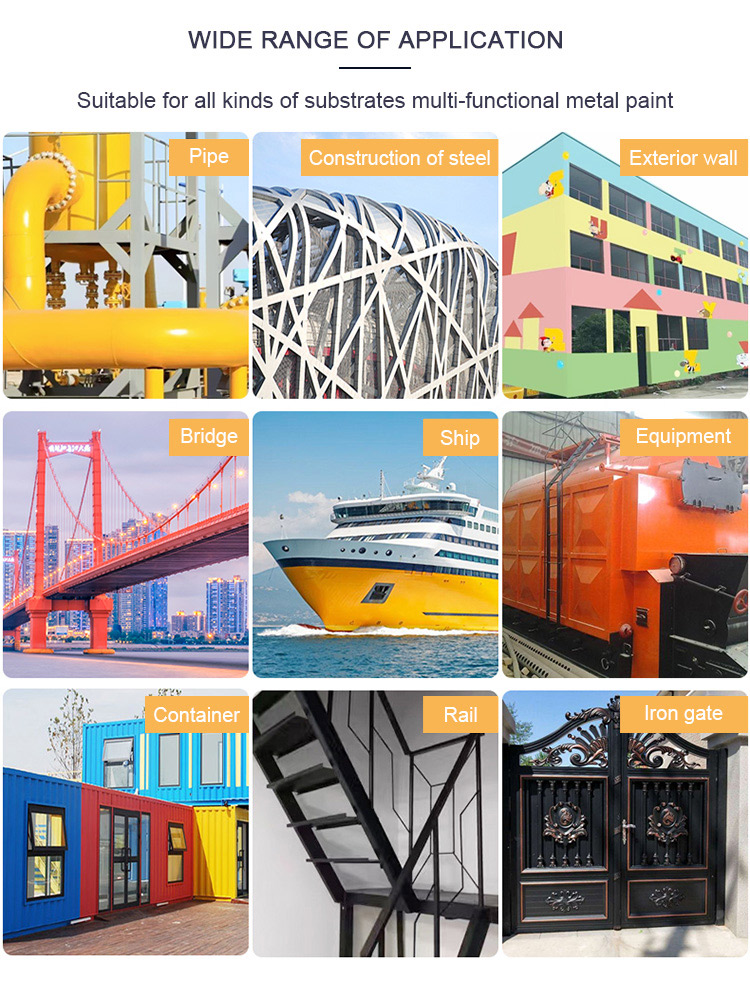

Scope of application

Product features

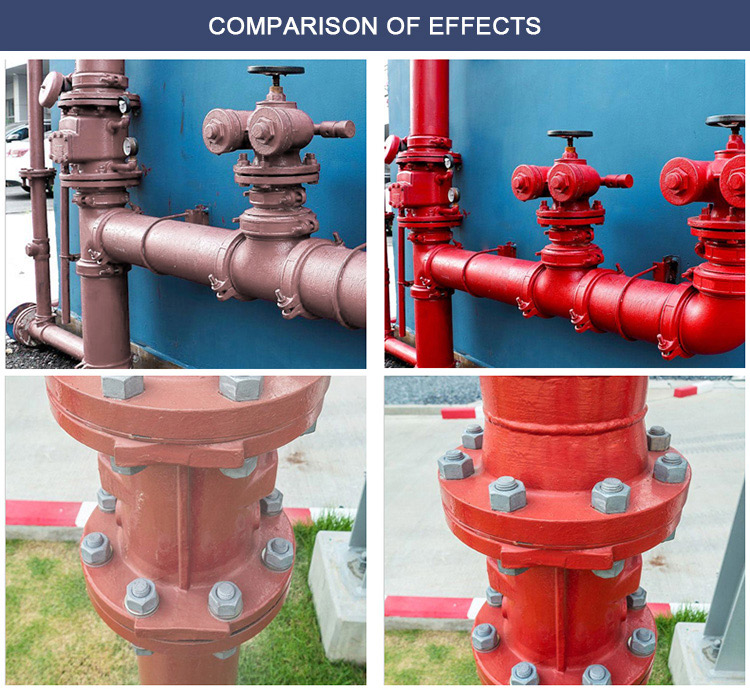

Fluorocarbon top paint has long weather resistance, excellent light retention, color retention, acid resistance, oil resistance, salt fog resistance, super pollution resistance, high strength and high gloss, and strong adhesion, dense film, good wear resistance, and has a good decorative; High grade topcoat with excellent anti-corrosion, decorative and mechanical properties for long-term coating in outdoor environment.

Application field

- Fluorocarbon anticorrosive topcoat is suitable for decorative and protective topcoat in urban atmosphere, chemical atmosphere, Marine atmosphere, strong ultraviolet irradiation area, wind and sand environment. Port terminal painting, Marine facilities anticorrosion, steel protection painting.

- Fluorocarbon anticorrosive paint in steel structure bridge paint, concrete bridge anticorrosive paint, metal curtain wall paint, building steel structure (airport, stadium, library), port terminals, coastal Marine facilities and other fields of protection.

Safety measures

The construction site should have a good ventilation environment to prevent the inhalation of solvent gas and paint fog. Products should be kept away from heat sources, and smoking is strictly prohibited at the construction site.

Storage and packaging

Storage: must be stored in accordance with national regulations, the environment is dry, ventilated and cool, avoid high temperature and far from the fire source.

Storage period: 12 months, after the inspection should be used after qualified.