Epoxy Zinc-Rich Primer Paint Epoxy Coating Ships Bridges Anti-corrosion Paint

Product Description

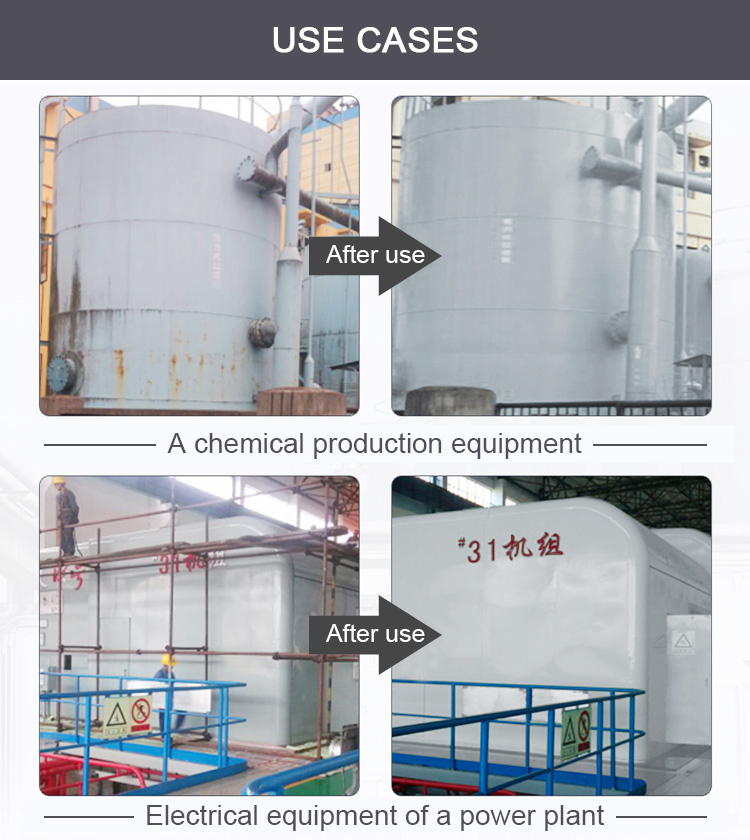

Epoxy zinc-rich primer as the high-performance primer is designed to provide superior rust and corrosion protection in the most demanding environments.

In addition to excellent rust protection, our epoxy zinc-rich primer is easy to apply and provides a smooth, even finish. Its two-component formula ensures a strong and long-lasting bond to the substrate, further enhancing its protective capabilities.

Main composition

Epoxy zinc-rich primer is a special coating product composed of epoxy resin, zinc powder, ethyl silicate as the main raw materials, with polyamide, thickener, filler, auxiliary agent, solvent, etc. The paint has the characteristics of fast natural drying, strong adhesion, and better outdoor aging resistance.

Main features

The key features of our epoxy zinc-rich primer is its excellent resistance to water, oil and solvents. This means it effectively protects metal surfaces from moisture, chemicals and other corrosive substances, ensuring the longevity of the coating structure.

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | Stocked item: 3~7 working-days Customized item: 7~20 working days |

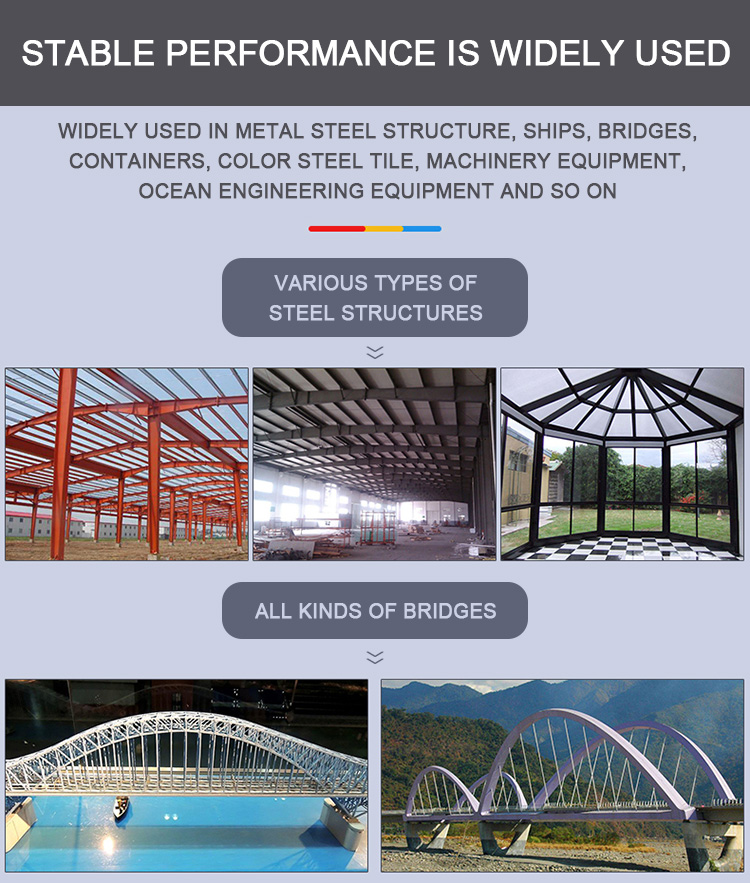

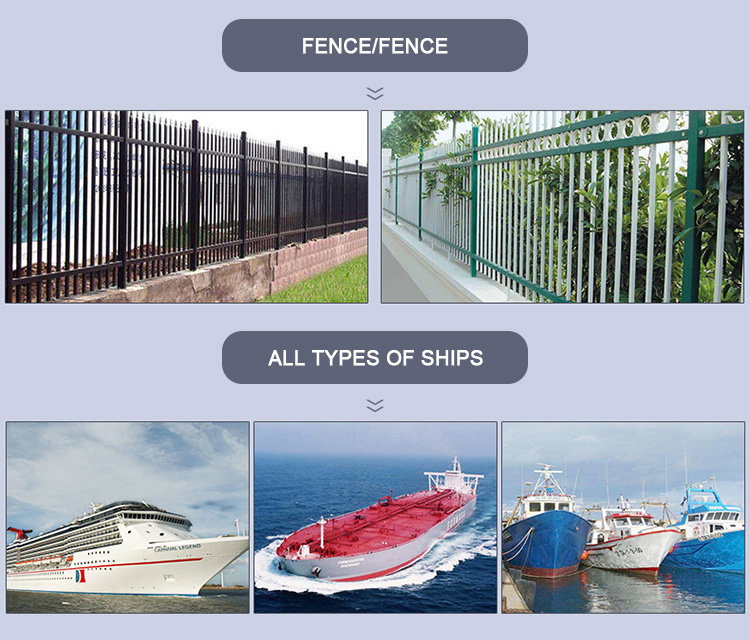

Main uses

Whether you are working in the marine, automotive or industrial sectors, our epoxy zinc-rich primers are a reliable solution for protecting metal surfaces from corrosion.Its proven performance in challenging environments makes it a trusted choice for professionals who prioritize the durability and longevity of their protective coatings.

Scope of application

Construction reference

1, The surface of the coated material must be free of oxide, rust, oil and so on.

2, The substrate temperature must be above 3 ° C above zero, when the substrate temperature is below 5 °C, the paint film is not solidified, so it is not suitable for construction.

3, After opening the bucket of component A, it must be stirred evenly, and then pour group B into component A under stirring according to the ratio requirement, fully mixed evenly, standing, and curing After 30 mins, add an appropriate amount of diluent and adjust to the construction viscosity.

4, The paint is used up within 6h after mixing.

5, Brush coating, air spraying, rolling coating can be.

6, The coating process must be constantly stirred to avoid precipitation.

7, Painting time:

| Substrate temperature (°C) | 5~10 | 15~20 | 25~30 |

| Minimum interval (Hour) | 48 | 24 | 12 |

The maximum interval should not exceed 7 days.

8, recommended film thickness :60~80 microns.

9, dosage: 0.2~0.25 kg per square (excluding loss).

Note

1, Diluent and dilution ratio: inorganic zinc-rich anti-rust primer special thinner 3%~5%.

2, Curing time: 23±2°C 20 minutes. Application time :23±2°C 8 hours. Coating interval: 23±2°C minimum 5 hours, maximum 7 days.

3, Surface treatment: the steel surface must be derusted by the grinder or sandblasting, to Sweden rust Sa2.5.

4, It is recommended that the number of coating channels: 2~3, in the construction, the application of the lift electric mixer will be A component (slurry) fully mixed evenly, should be used while stirring construction. After supporting: all kinds of intermediate paint and top paint produced by our factory.

Transportation and storage

1, Epoxy zinc-rich primer in transportation, should prevent rain, sunlight exposure, to avoid collision.

2, Epoxy zinc-rich primer should be stored in a cool and ventilated place, prevent direct sunlight, and isolate the fire source, away from the heat source in the warehouse.

Safety protection

The construction site should have good ventilation facilities, painters should wear glasses, gloves, masks, etc., to avoid skin contact and inhalation of paint mist. Fireworks are strictly prohibited at the construction site.