Chlorinated rubber primer Environmental protection durable anticorrosive paint

Product Description

Chlorinated rubber primer is a multi-purpose primer, which can be widely used in metal, wood and non-metal surfaces in aviation, Marine, water sports and other fields. Chlorinated rubber sole has excellent water resistance, oil resistance, acid and alkali resistance, salt spray resistance and other properties, is a high strength, high adhesion primer.The main materials of chlorinated rubber primer include primer, diluent, main hardener, assistant hardener and so on. According to different engineering requirements, the corresponding formula and materials are selected.

Main features

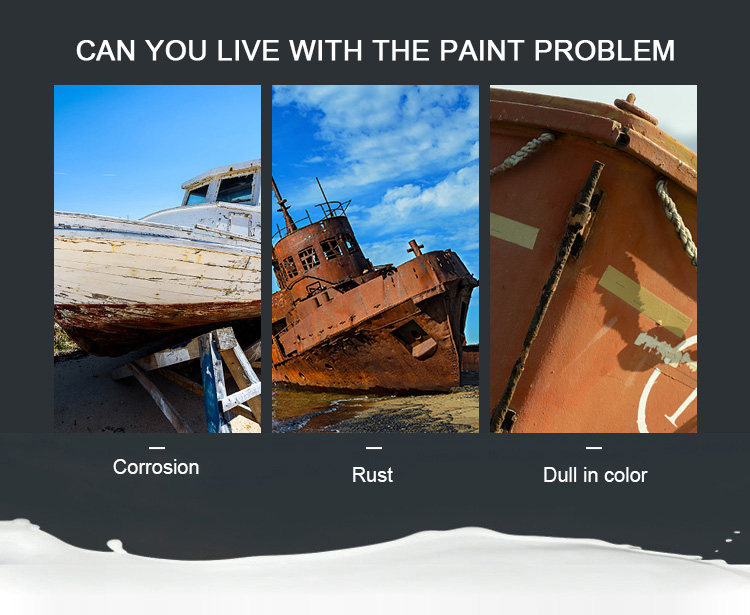

- Chlorinated rubber is a kind of chemically inert resin, good film forming performance, water vapor and oxygen permeability to the film is small, therefore, chlorinated rubber coating can resist moisture corrosion in the atmosphere, acid and alkali, seawater corrosion; The permeability of water vapor and oxygen to the film is low, and it has excellent water resistance and good corrosion resistance.

- Chlorinated rubber paint dries quickly, several times faster than ordinary paint. It has excellent low temperature construction performance, and can be constructed in an environment of -20℃-50℃; The paint film has good adhesion to steel, and the adhesion between layers is also excellent. Long storage period, no crust, no caking.

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | stocked item: 3~7 working-days customized item: 7~20 working days |

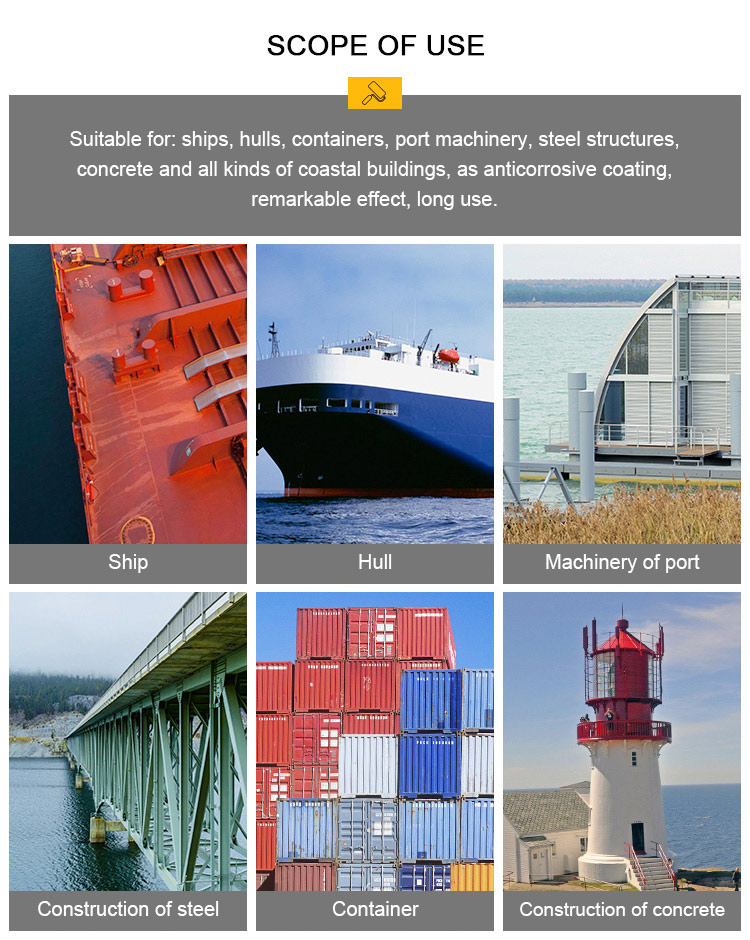

uses

Construction method

Airless spraying is recommended to use 18-21 nozzles.

Gas pressure170~210kg/C.

Brush and roll apply.

Traditional spraying is not recommended.

Diluent special diluent (not exceeding 10% of total volume).

Drying time

Surface dry 25℃≤1h, 25℃≤18h.

Storage life

The effective storage life of the product is 1 year, expired can be checked according to the quality standard, if meet the requirements can still be used.

Note

1. Before use, adjust the paint and diluent according to the required ratio, match how much to use stir evenly before use.

2. Keep the construction process dry and clean, and do not contact with water, acid, alkali, etc

3. The packing bucket must be tightly covered after painting to avoid gelling.

4. During construction and drying, the relative humidity shall not be greater than 85%, and the product shall be delivered 2 days after coating.