Alkyd Antirust Primer Good Adhesion Corrosion Resistance Alkyd Coating

Product Description

Alkyd antirust primer has good gloss and mechanical strength, natural drying at room temperature, solid paint film, good adhesion and outdoor weather resistance...... Alkyd antirust primer paint is applied to steel, steel structure, it is used before alkyd finish paint. The colors of the primer paint are gray, rust and red lead . The material is coating and the shape is liquid. The packaging size of the paint is 4kg-20kg. Its characteristics are strong adhesion and easy construction.

Alkyd anti-rust paint is composed of alkyd resin as base material, adding anti-rust pigment, auxiliary agent and solvent. It has good adhesion. Anti-rust properties. Fast drying, good adhesion, convenient construction.Before coating, the paint should be stirred evenly. lf the viscosity is too high, appropriate amount of water can be added, the amount of 5%-10%. Strain the edge of the coating and stir to ensure the uniform paint.

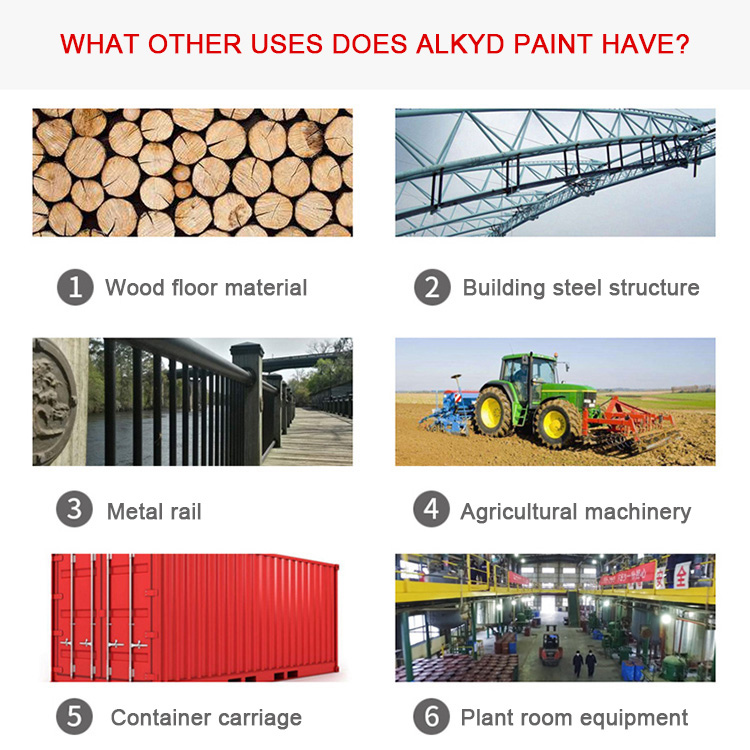

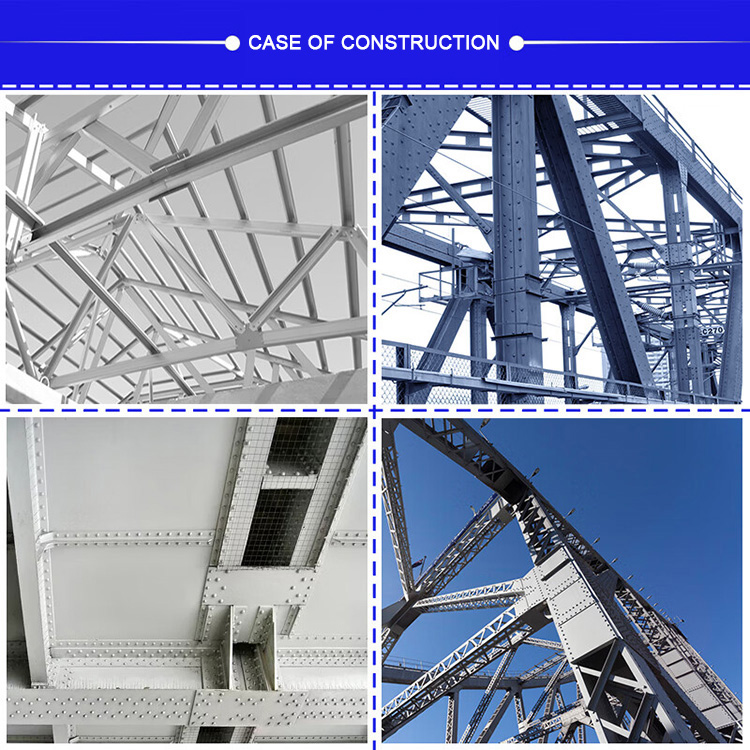

Application field

Used for anti-rust coating of mechanical equipment and steel structure.Steel structures, large vehicles, ship facilities, iron guardrails, Bridges, heavy machinery...

A primer recommended:

1. Such as stainless steel, galvanized steel, glass steel, aluminum, copper, PVC plastic and other smooth surfaces must be coated with special primer to enhance adhesion and avoid paint loss.

2. Ordinary steel to see your requirements, with primer effect is better.

Specifications

| Appearance of coat | The film is smooth and bright | ||

| Color | Iron red, gray | ||

| drying time | Surface dry ≤4h (23°C) Dry ≤24 h(23°C) | ||

| Adhesion | ≤1 level (grid method) | ||

| Density | about 1.2g/cm³ | ||

|

Recoating interval |

|||

|

Substrate temperature |

5℃ |

25℃ |

40℃ |

| Short time interval |

36h |

24h |

16h |

| Time length |

unlimited |

||

| Reserve note | Before preparing the coating, the coating film should be dry without any contamination | ||

Product features

The alkyd anti-rust paint is composed of alkyd resin as the base material, adding anti-rust pigments, additives and solvents. It has good adhesion. Anti-rust properties. Fast drying, good adhesion, convenient construction.

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | Stocked item: 3~7 working-days Customized item: 7~20 working days |

Coating method

Construction conditions: substrate temperature is higher than 3°C to prevent condensation.

Mixing: Stir the paint well.

Dilution: You can add an appropriate amount of supporting diluent, stir evenly and adjust to the construction viscosity.

Safety measures

The construction site should have a good ventilation environment to prevent the inhalation of solvent gas and paint fog. Products should be kept away from heat sources, and smoking is strictly prohibited at the construction site.

First aid method

Eyes: If the paint spills into the eyes, wash immediately with plenty of water and seek medical attention in time.

Skin: If the skin is stained with paint, wash with soap and water or use an appropriate industrial cleaning agent, do not use large amounts of solvents or thinners.

Suction or ingestion: Due to the inhalation of a large amount of solvent gas or paint mist, should immediately move to the fresh air, loosen the collar, so that it gradually recover, such as ingestion of paint please seek medical attention immediately.

Storage and packaging

Storage: must be stored in accordance with national regulations, the environment is dry, ventilated and cool, avoid high temperature and away from fire.