Alkyd Antirust Primer against corrosion rust industrial coatings

Product Description

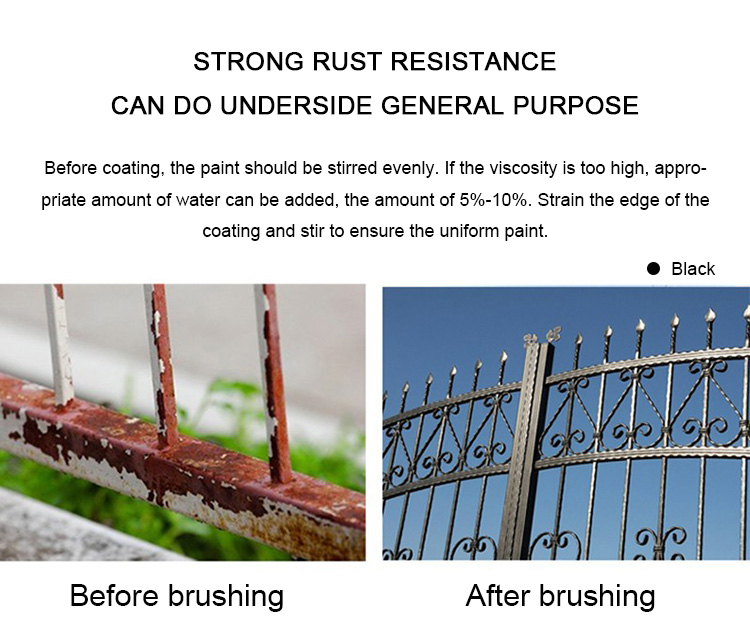

Our alkyd anti-rust primers are carefully designed to adhere to a wide range of metal substrates, including steel, iron and other ferrous metals, making them ideal for a variety of industrial, automotive and Marine applications. Whether you are working on a new construction project or performing maintenance on an existing structure, our primers are the perfect solution for preparing metal surfaces for painting and coating.

Product Features

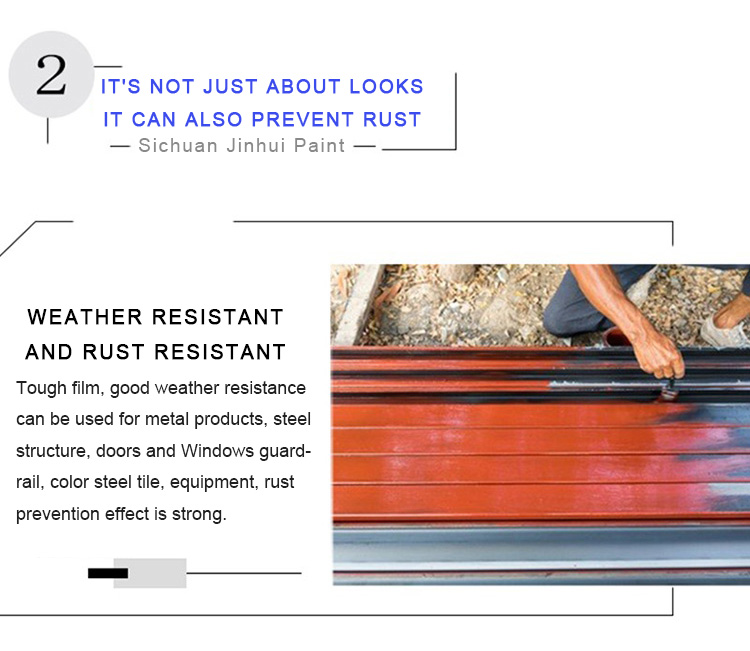

- One of the main features of our alkyd anti-rust primers is their quick-drying formula, which speeds up construction and reduces downtime. This means you can complete the project more efficiently without compromising the quality of the finished product. In addition, the excellent adhesion of the primer ensures that the topcoat adheres firmly to the surface, resulting in a smooth, even surface effect.

- Our primers are also moisture and chemical resistant, providing additional protection in harsh environments and ensuring long-term durability. Our alkyd anti-rust primers have excellent anti-rust properties and are an essential part of any metal protection system, extending the life of metal surfaces, giving you peace of mind and long-term cost savings.

- In addition to their superior properties, our alkyd anti-rust primers are easy to apply and suitable for professional painters and DIY enthusiasts. Its low odor and low VOC content also make it a safer and more environmentally friendly choice for indoor and outdoor applications.

Specifications

| Appearance of coat | The film is smooth and bright | ||

| Color | Iron red, gray | ||

| drying time | Surface dry ≤4h (23°C) Dry ≤24 h(23°C) | ||

| Adhesion | ≤1 level (grid method) | ||

| Density | about 1.2g/cm³ | ||

|

Recoating interval |

|||

|

Substrate temperature |

5℃ |

25℃ |

40℃ |

| Short time interval |

36h |

24h |

16h |

| Time length |

unlimited |

||

| Reserve note | Before preparing the coating, the coating film should be dry without any contamination | ||

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | Stocked item: 3~7 working-days Customized item: 7~20 working days |

Coating method

Construction conditions: substrate temperature is higher than 3°C to prevent condensation.

Mixing: Stir the paint well.

Dilution: You can add an appropriate amount of supporting diluent, stir evenly and adjust to the construction viscosity.

Safety measures

The construction site should have a good ventilation environment to prevent the inhalation of solvent gas and paint fog. Products should be kept away from heat sources, and smoking is strictly prohibited at the construction site.

First aid method

Eyes: If the paint spills into the eyes, wash immediately with plenty of water and seek medical attention in time.

Skin: If the skin is stained with paint, wash with soap and water or use an appropriate industrial cleaning agent, do not use large amounts of solvents or thinners.

Suction or ingestion: Due to the inhalation of a large amount of solvent gas or paint mist, should immediately move to the fresh air, loosen the collar, so that it gradually recover, such as ingestion of paint please seek medical attention immediately.

Storage and packaging

Storage: must be stored in accordance with national regulations, the environment is dry, ventilated and cool, avoid high temperature and away from fire.